Polyethylene – Colour masterbatch

|

Title |

POLYMER FAILURE ANALYSIS INVESTIGATION; CREAM MASTERBATCH UNDERGOING PINKING DISCOLORATION |

|

Date |

2013 |

|

Objective |

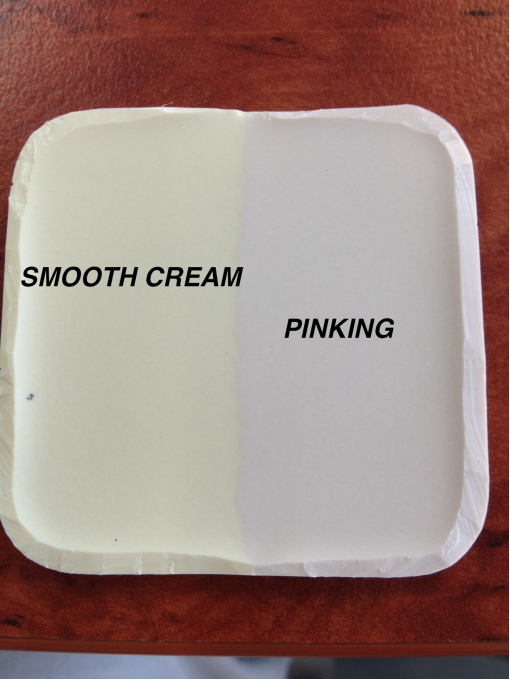

To carry out an examination of the three colour masterbatch products. |

|

Photo |

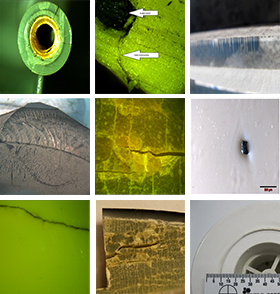

Figure 1. Colour shifting occurring with the polymer containing the ELJ21250masterbatch after weathering |

|

Testing Undertaken |

Accelerated weathering Colorimeter Colour Space Measurements EDAX NMR |

|

Failure Analysis |

The masterbatch contained a yellow dye that faded when exposed to UV light thus changing the observed colour balance shifts from yellow to pink due to the highlighting of the underlying iron oxide red tints. |

Polyethylene – Container

|

Title |

INVESTIGATION OF FAILURE OF A POLYETHYLENE INTERMEDIATE BULK CONTAINER (IBC) |

|

Date |

2013 |

|

Objective |

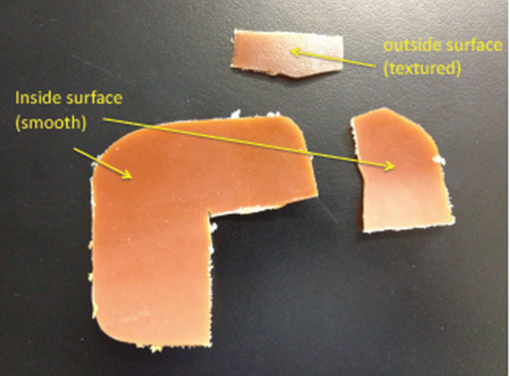

To investigate the cause of a cracking failure of a HDPE intermediate bulk container (IBC) |

|

Photo |

Figure 1. Samples as received |

|

Testing Undertaken |

EDAX elemental scans DSC thermal analysis OIT Carbonyl Index Measurements |

|

Failure Analysis |

The samples of the failed tank underwent oxidative embrittlement. Fracture could have occurred during normal handling of the tank as the material was extensively degraded and very brittle. |

Polyethylene – Electrofusion weld

|

Title |

FAILED ELECTROFUSION WELD FITTING |

|

Date |

2012 |

|

Objective |

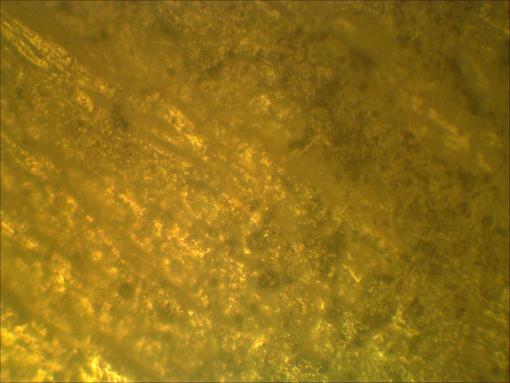

To assess the reason for the failure of an electrofusion fitting. |

|

Photo |

Figure 1. Interior of electrofusion fitting showing the very limited amount of fusion around the heating coils area and no fusion along any other part of the fitting |

|

Testing Undertaken |

Failure analysis |

|

Failure Analysis |

Failure may have been caused by out of round pipes, lack of, or inadequate cleaning/scraping of the pipe or the time of application of electrical current to the fitting being too short to allow fusion to occur. The failed joint had not been heated for long enough for an adequate amount of fusion to occur |

Polyethylene – Milk bottles

|

Title |

IDENTIFICATION OF CONTAMINANTS |

|

Date |

2013 |

|

Objective |

To identify contaminants found in two separate milk bottles. |

|

Photo |

Figure 1a and 1b (x200 mag). Black contaminant (stain) on inside of bottle wall

Figure 2. Red contaminant |

|

Testing Undertaken |

IR spec Microscopy DSC |

|

Conclusion |

IR spec of the black contaminant showed characteristics of polyethylene and spreads in a similar way to oils, thus is likely a degraded polyoil. IR spec of the Red contaminant also showed characteristics of that of polyethylene |

Polyethylene – Rotomolded tank

|

Title |

FAILURE ANALYSIS OF ROTOMOLDED POLYETHYLENE TANK |

|

Date |

2013 |

|

Objective |

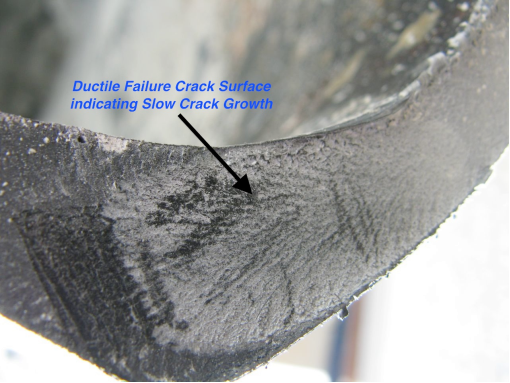

To determine the causes of failure of a large polyethylene water tank used to aerate mine water at a gold mine |

|

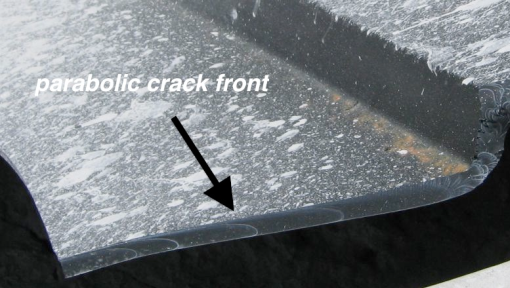

Photo |

Figure 1. Failed and collapsed tank

Figure 2. Fracture surface near base of tank showing initiation site of fracture. The changing crack surface morphology reflected the change in the speed of the crack.

Figure 3. Textured patterns associated with ductile slow crack growth in tank wall near location of lower outlet penetration. Note radiating crack fronts

Figure 4. Lower-mid side wall of tank showing parabolic crack fronts.

Figure 5. Lower-mid side wall of tank showing ductile tearing |

|

Testing Undertaken |

Failure analysis |

|

Failure Analysis |

Tank failure was partly due to its installation and partly due to its mode of use where it was subject to a higher SG performance and stresses for which the tank design did not adequately cater. The investigation showed that the initiation site of failure was at the lower tank wall in the immediate vicinity of the outlet penetration. The addition of metal reinforcing bands for the lower side-wall would have lessened the destructive hoop stresses on the lower side wall and hence avoided the failure of the tank. |

Polyethylene – Sheet (1 of 2)

|

Title |

DEGRADED INCLUSION DEFECTS IN HDPE SHEET |

|

Date |

2013 |

|

Objective |

To investigate the nature and effect of inclusion defects in HDPE geomembrane sheet |

|

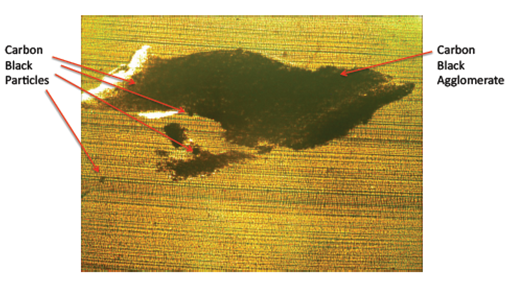

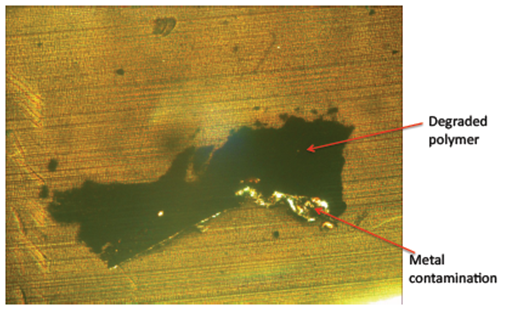

Photo |

Figure 1. Inclusion at 100x mag

Figure 2. Inclusion at 100x mag |

|

Testing Undertaken |

Sectioning by microtoming Transmission optical microscopy (TOM) |

|

Conclusion |

Figure 1 inclusion was identified as a carbon black agglomerate since discrete aggregates of carbon black particles were visible in transmission.

Figure 2 inclusion was identified as a lump of degraded and carbonized polymer containing a fragment of metal suggesting this inclusion originated from the extruder barrel or screw. |

Polyethylene – Sheet (2 of 2)

|

Title |

SCRATCH-MARKS ON HDPE SHEET |

|

Date |

2013 |

|

Objective |

To investigate the effect of scratch marks in HDPE sheet |

|

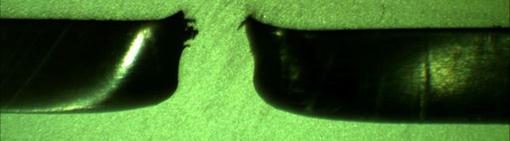

Photo |

Figure 1. Tensile specimen

Figure 2. Tensile specimen breaks at scratch

|

|

Testing Undertaken |

Sectioning and microscopy Tensile testing (ASTM D 6693) NCTL (ASTM D 5397) |

|

Failure Analysis |

The scratches were found to reduce the break elongation and the break tensile strength. Stress crack test was ongoing at 300 hours prior to any breaks being observed. |